2025 Videos for Application Examples on IAI General Catalog and Digest Catalog

40+ Application Example Animations/videos are from 2025 IAI Digest Catalog

40+ Application Example Animations/videos are from 2025 IAI Digest Catalog

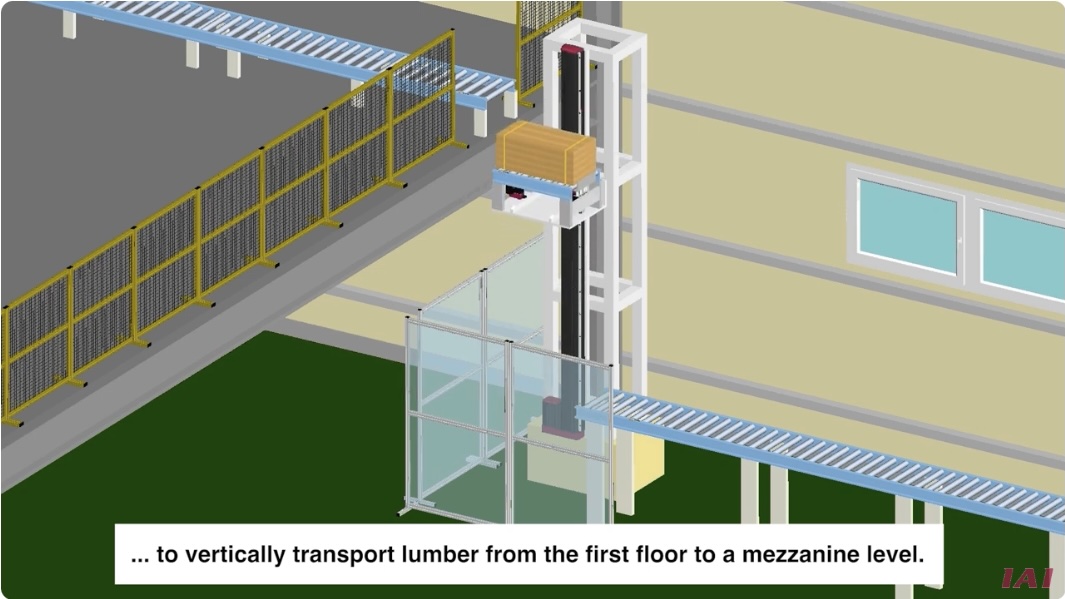

Application Example: Lumber Vertical Lift Transport – A Ultra-large Slider is adopted – New Models with 120kg vertical payload – EC-S18(X)LFR

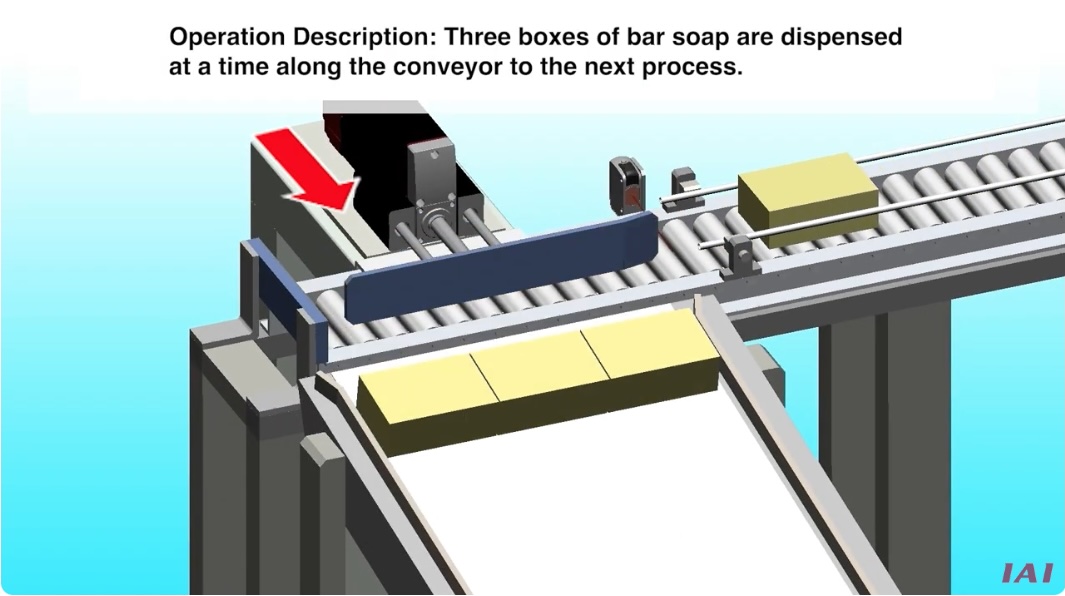

Application Example: Bar Soap Dispensing Process – A Mini Rod Series is adopted – New Models with 100mm stroke – EC-GD4 (with guide) and EC-RP4

Wire Cylinder – Motorized and yet tiny (cylinder I.D. ø6~8). An industry first! New drive system. Because the actuator and wire controller are separate …The heat source can be separated

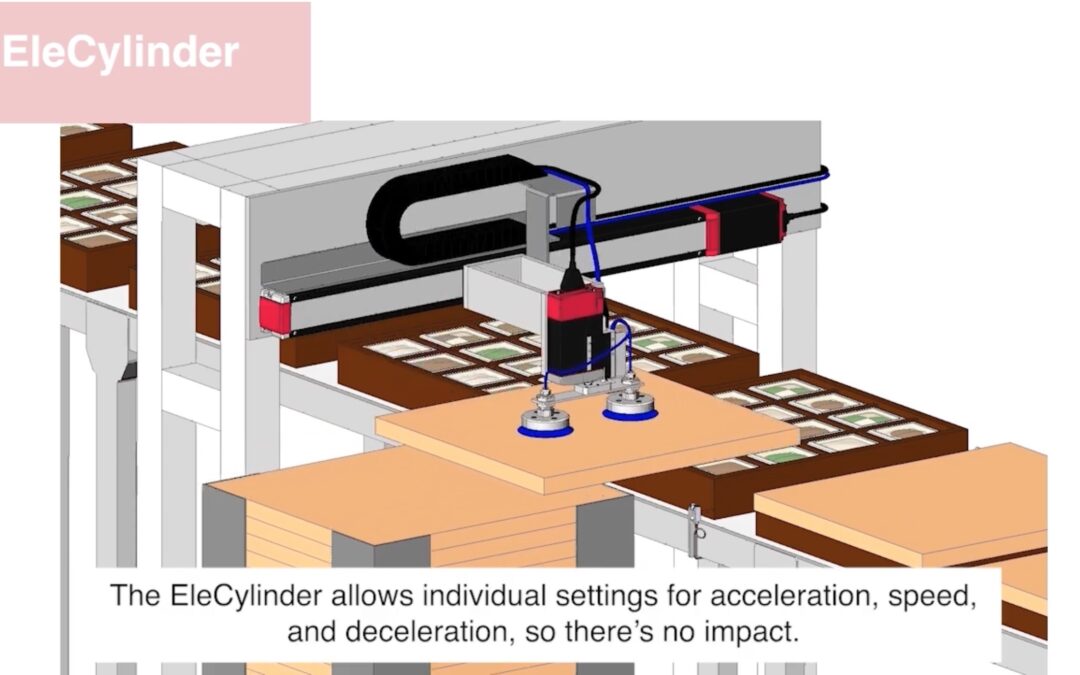

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.

The inspection camera is brought to a smooth standstill by adjusting acceleration and deceleration. This can significantly reduce standby time due to camera vibration.