What is CODESYS (CODESYS for XSEL2)?

- CODESYS is a PLC software and peripheral functions compliant with the international PLC programming language standard IEC 61131-3, developed by CODESYS GmbH.

- Among the peripheral functions, XSEL2 adopts the EtherNet/IP scanner and OPC UA server.

- Dedicated programming software (comprehensive development environment) is provided.

Communication is possible across multiple industrial network barriers (standards).

- Data collection within factories

- Ex.: MES (production execution system which grasps and manages the manufacturing process as well as providing directions and support to workers)

- SCADA (system which uses a network to collect, monitor, and control equipment and facility information)

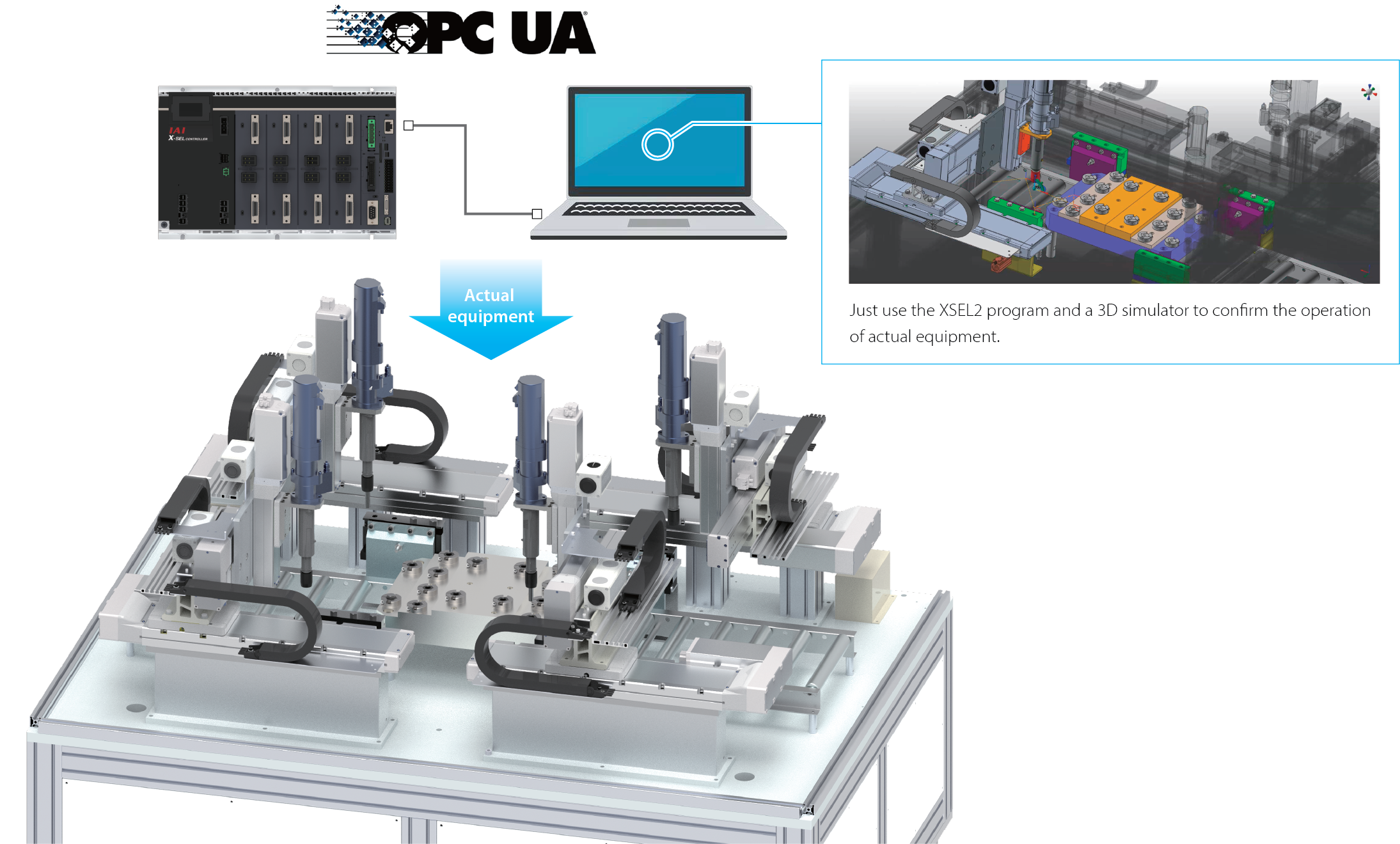

- Digital observation and startup (offline teaching)

Actuator operation can be confirmed on a 3D simulator by programming with the XSEL2 PLC function and transferring to the 3D simulator with OPC UA.

With the XSEL2 as the master, connection with various devices, including IAI devices, is possible.

- Fan speed monitor

- Motor overload status monitor

- Predicting internal capacitor life based on temperature and operating time

- Monitoring present position, motor current value, and maintenance information.

(Maintenance information: Number of travel cycles, running distance, etc.)

Actuator information can now be confirmed with teaching tools. There is also an area where customers can freely write information to the actuator.

Ex.:

- Timer

- Counter

- Edge detection, etc.

- Home return

- Servo ON/OFF

- Direct value specified travel, etc.

Ex.: Servo ON → Home return → Linear interpolating travel to registered position No. (reciprocal motion)

Connect the ELECYLINDER, CCM, and Robot Pump

directly to the ELECYLINDER connection module for control.

Additionally, REC can be connected via EtherNet/IP.

- SEL commands

- PLC function program

- Communication via PIO or field network

Simulator function

Supports 3D model positioning, interference checks, and offline teaching.

SEL Program Generator function

Reads in DXF data and converts it to a position program.

Teaching Tools

Monitor data output function

Information such as present position or overload level can be output to the PLC with this function.

Error countermeasure search function

Search for an error code to display error content details and countermeasures.

Stay Informed by Following Us