2 Boxes are pushed against the positioning plate.

2 Printing by ink jet printer.

Past problems

Increased initial cost of the facility

In the previous facility, purchase costs for air cylinder, reed switches, speed controllers, solenoid valve, air filter and lubricator were incurred. Also incurred were design, assembly and adjustment expenses for piping and wiring.

Speed was not constant and operations were not stable.

The air cylinder changed its speed due to fluctuations of air source pressure caused by different temperatures depending on the season or time of day.

Because of this, it took 30 minutes per day on average to adjust the speed controllers and reed switches before the startup of operation and after maintenance.

After installation of an ELECYLINDER®

Reduced initial cost

The ELECYLINDER consists of the main body (with built-in controller) and a cable only, reducing overall costs.

Cost comparison Air cylinder and ELECYLINDER (motorized)

| Air cylinder |

device |

Device using an |

ELECYLINDER |

| Item | Cost | Item | Cost |

| Air cylinder (double guide type) | $146 | ELECYLINDER(built-in guide type) | $391 |

| Design/assembly/ adjustment expenses (6 hours) |

$300 | Design/assembly/ adjustment expenses (1 hour) |

$50 |

| Reed switch (2 units) | $44 | Cable | $50 |

| Pipe coupling | $6 | - | - |

| Solenoid valve | $69.50 | - | - |

| Pressure regulator + air filter + lubricator |

$60 | - | - |

| Speed controller (2 units) |

$8 | - | - |

| Air piping (3 meters) |

$30 | - | - |

| Sensor wiring (3 meters) |

$30 | - | - |

| Total for air cylinder facility |

$693.50 | Total for ELECYLINDER facility |

$491 |

Difference $202.50

Reduced labor cost

Operations are not affected by different temperatures depending on the season or time of day.

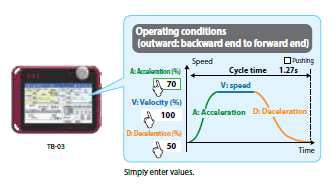

The ELECYLINDER can set A (acceleration), V (velocity) and D (deceleration) at desired values, after which no adjustment is needed.

As a result, cardboard boxes are not damaged because of high speed, or passed through due to slow speed.

Adjustment time for speed controllers and reed switches: 30 minutes / day

ELECYLINDER adjustment time

Once the speed is set, it will always be constant. 0 minute / day

*Exchange Rate: 1(USD)=100(Japanese Yen)