System Overview :

Improvement Overview :

Device for putting syrup on doughnuts on a conveyor belt.

Replacing an air cylinder with an ELECYLINDER ® to move and dispense syrup.

Description of Operation

1 Doughnuts move along a conveyor belt.

2 A container of syrup moves across the conveyor belt and puts syrup on doughnuts.

Before Improvement

Improvement Effects

Past problems

In case of an air cylinder

Because movement of the air cylinder was unstable, syrup was put on the doughnuts unevenly.

A worker had to add syrup by hand to doughnuts that did not get enough syrup.

Why wasn't the movement stable…

After installation of an ELECYLINDER®

In case of an ELECYLINDER

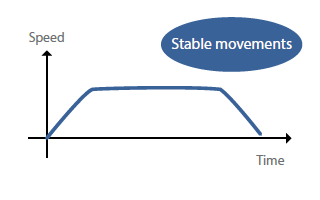

The ELECYLINDER consistently operates at a preset speed, which makes the amount of syrup on each doughnut the same.

Because of this, workers do not need to add syrup by hand.

Why is movement stable…

Conditions

| Labor Cost |

$12 / hr |

| Annual operation days | 350 days / year |

Description

Labor cost for adding syrup manually

In case of an air cylinder

1 hour/day x $12/day x 350 days = $4,200.

In case of an ELECYLINDER

$0.00

Annual labor cost savings is $4,200 because the additional manual work of 1 hour / day is eliminated.

The above application example and results including numbers are introduced from one of our product user's event and experience.

*Exchange Rate: 1(USD)=100(Japanese Yen)

*Exchange Rate: 1(USD)=100(Japanese Yen)