Shampoo Filling Equipment

Equipment Overview

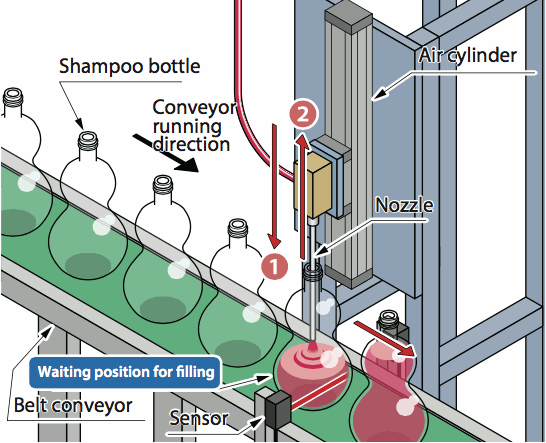

- Equipment for filling special bottles with shampoo. (10,000 bottles per day)

- Filling is performed by moving a nozzle upward as the liquid surface goes up.

Before Improvement

➤ A conveyor transfers empty bottles and stops at the waiting position for filling as a sensor detects the bottle.

➤ An air cylinder lowers the nozzle to the position just before the bottom of the bottle. The air cylinder starts going up as shampoo filling starts.

➤ After a certain volume is filled, the nozzle keeps going up and stops at the position where the nozzle tip is out of the bottle opening.

➤ The filled bottle is transferred to the next process.

Process points

1. Shampoo is dispensed from the nozzle at a constant rate.

2. Rising speed of the liquid surface is not constant; it is slower at the larger cross section and faster at the smaller cross section.

3. Therefore, the distance between the nozzle and the liquid surface is not constant.

4. To prevent foaming, the distance between the nozzle and the liquid surface should be within a certain distance.

Problems

➤ When speed of the air cylinder was slow, the nozzle plunged in the liquid, causing drips of shampoo on the outside of the bottle and conveyor after filling.

➤ It was necessary to clean up the drips on the bottle and conveyor.

After Improvement

✪ The air cylinder has been replaced by a ROBO Cylinder.

Improvements

✪ Clean up work of shampoo drips was no longer needed.

✪ Since the speed of the ROBO Cylinder can be changed in motion, the distance between the nozzle and the liquid surface can be kept optimum.

✪ Because of this, the nozzle does not plunge into the liquid, eliminating shampoo drips on the outside of the bottle.

✪ Quality has become steady and rejected products due to bubbles have been eradicated.

✪ The working hours has been reduced by 60 minutes per day.

Clean up time of 60 minutes per day has been eliminated.

✪ Annual saving for labor cost is $2,900.

$12 x 60 minutes (10 min. x 6 times) = $2,880.

*Exchange Rate: 1(USD) = 100(Japanese Yen)

Please call IAI America from 8:30 am to 5:00 pm at these locations:

Eastern U.S. office: (678) 354-9470

Central U.S. office: (800) 944-0333

Western U.S. office: (800) 736-1712

Outside office hours, please use our contact form.