Expiry Date Printing Equipment

Equipment Overview

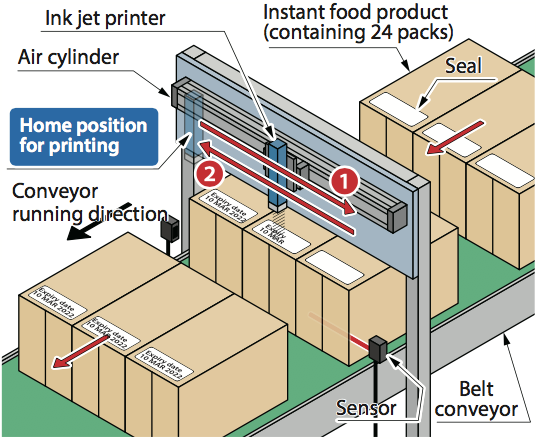

- Equipment for printing expiry dates on cardboard boxes packed with instant food products for shipping. (84,000 units / day)

- Expiry dates are printed on the carton boxes aligned and placed in position.

Before Improvement

➤ Cardboard boxes (3 boxes in a row) are transferred by conveyor and stop as a sensor detects them.

➤ An air cylinder equipped with an ink jet printer moves to direction ❶ during which printing is performed on the labels of three boxes.

➤ After printing, the air cylinder shifts to direction ❷ and moves the ink jet printer to the home position.

➤ The cardboard boxes are transferred to the next process.

Problems

➤ Because of improper start timing of the air cylinder, expiry dates were sometimes printed off the label.

➤ Due to speed fluctuations of the air cylinder, the expiry dates were sometimes printed off the label.

➤ When a date was printed off the label, the conveyor had to be stopped to adjust the speed controller.

➤ Air cylinder adjustments and re-packing of products with improper printing (10 minutes) were carried out twice a day.

➤ There were 3 workers involved in the production line. While one worker was doing re-adjustment, waiting time occurred for the other two workers.

Improved Equipment

✪ The air cylinder has been replaced by an ELECYLINDER.

Improvements

✪ There is no delay in starting the ink jet printer .

✪ The ink jet printer can be operated at an optimum speed as specified.

✪ There is no need to re-adjust the start timing and speed of the ink jet printer.

✪ Non-productive wait time for the 3 workers has been eliminated.

✪ The working hours has been reduced by 20 minutes per day.

Waiting time of 20 minutes per day for re-adjustment has been eliminated.

✪ Annual saving for labor cost is US $3,600.

US$15 x 20 minutes (10 min. x 2 times) x 240 days = US$3,600.

*Exchange Rate: 1 (USD) = 100 (Japanese Yen). (Condition: Labor cost US$15/hr, Annual operation 240 days.)

Please call IAI America from 8:30 am to 5:00 pm at these locations:

Eastern U.S. office: (678) 354-9470

Central U.S. office: (800) 944-0333

Western U.S. office: (800) 736-1712

Outside office hours, please use our contact form.